- 888-692-7638

- 111 SW Columbia Street, Suite 1080, Portland OR, 97201, USA

- White Paper/ 02 Apr, 2013

Overview

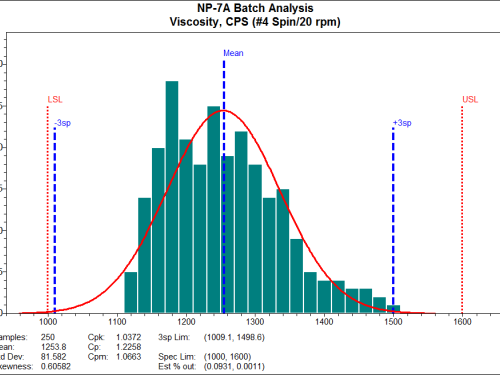

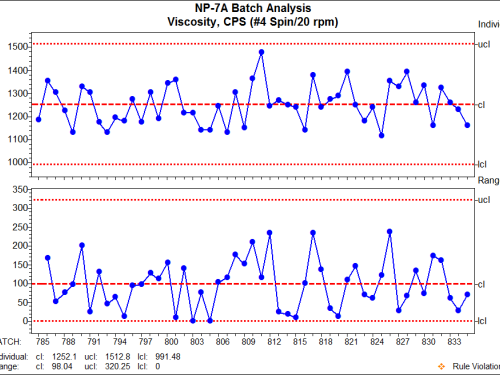

Predictive maintenance (PdM) methods actively monitor process and equipment parameters to determine optimal timing for maintenance. Control charts are used to monitor performance, trigger maintenance activity and improve Overall Equipment Effectiveness (OEE) for more productive manufacturing systems. Using process based analytics enables event-driven maintenance which produces better product at lower cost with less downtime.

- White Paper/ 07 Feb, 2013

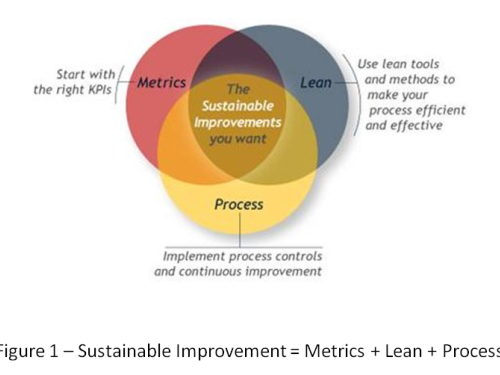

To compete in today’s global markets, manufacturers need to actively use modern manufacturing operations management systems. These systems, in turn, depend on enterprise manufacturing intelligence (EMI) which extends process based analytics throughout company operations.

- White Paper/ 28 Jan, 2013

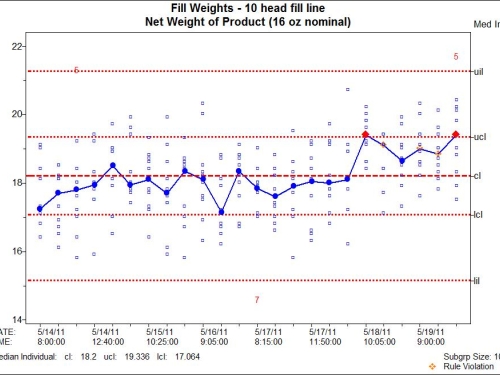

Manufacturers are always trying to increase throughput while maintaining process stability and product quality. One common solution is to deploy equipment which simultaneously produces multiple units with each cycle. This type of equipment includes multi-head fillers, multi-cavity molding and multi-spindle machining centers. These manufacturing applications are often referred to as “family processes”.

- Article/ 05 Nov, 2012

In today’s global markets, the pressure to perform is non-stop and the need for information is real-time. To maximize competiveness and profitability, the supply chain needs top-notch data management. But, that by itself is not enough. The data must be aggregated and analyzed to deliver complete manufacturing intelligence (MI) that, in turn, enables sound decision making for effective supply chain management.

The Model for Successful Supply Chain Management