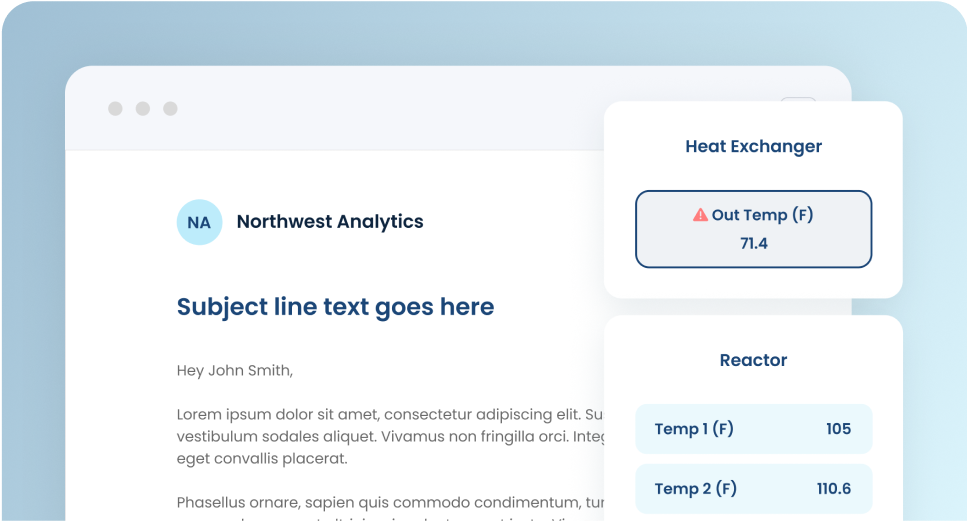

“If you’re having an issue at your plant, your technology center experts can also see that data and help you with solutions.”

Homepage

Northwest Analytics' solutions transform process data into actionable insights that reduce waste while increasing efficiency and product yield.

.png)

Drive Operational Excellence at Scale

Gain visibility across sites with performance dashboards and actionable insights. Leverage retained expertise to reduce variability, improve quality, and support strategic decision-making.

$1M-$2M

Average annual savings per plant

25%

Less unplanned downtime

1-3

Week implementation

Turn Data into Process Insights

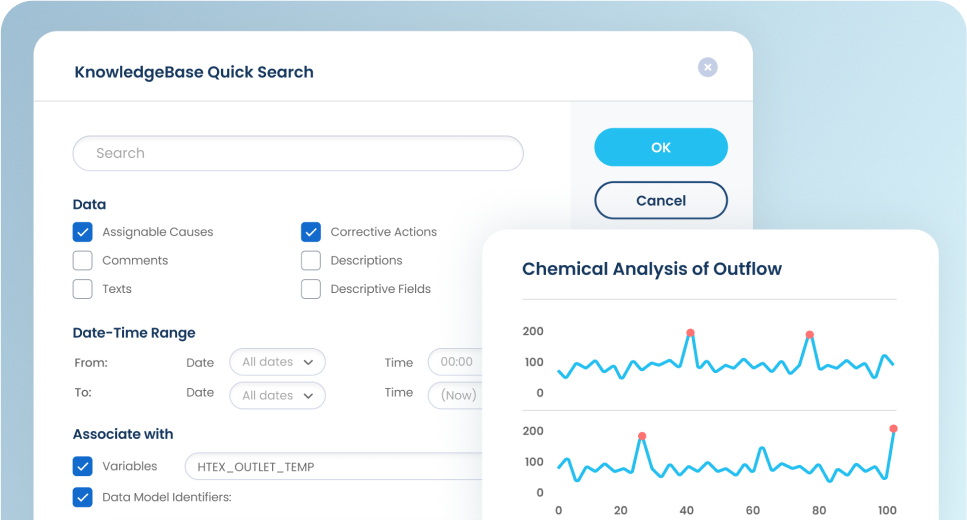

Analyze trends, identify root causes, and drive continuous improvement using real-time analytics and historical context. ACCA tools help preserve process knowledge and accelerate troubleshooting.

53

Working Days Saved Annually

25%

Less Product Waste

40%

Faster root cause

Stay in Control, Shift After Shift

Monitor process performance in real time with intuitive SPC charts and dashboards. Capture and apply expert knowledge to resolve issues faster and keep production running smoothly.

3,000+

Manufacturing Deployments

35%

Prime Manufacturers

$700M+

Customer Savings

NWA Analytics Knowledge Suite®

Avoid unplanned downtime with real-time alerts and automated dashboards.

NWA Quality Analyst®

Detect future process deviations before they happen with advanced analytics and SPC charting.

NWA Focus EMI®

Generate actionable process insights with real-time dashboards, role-based visualizations and customizable alarm notifications.

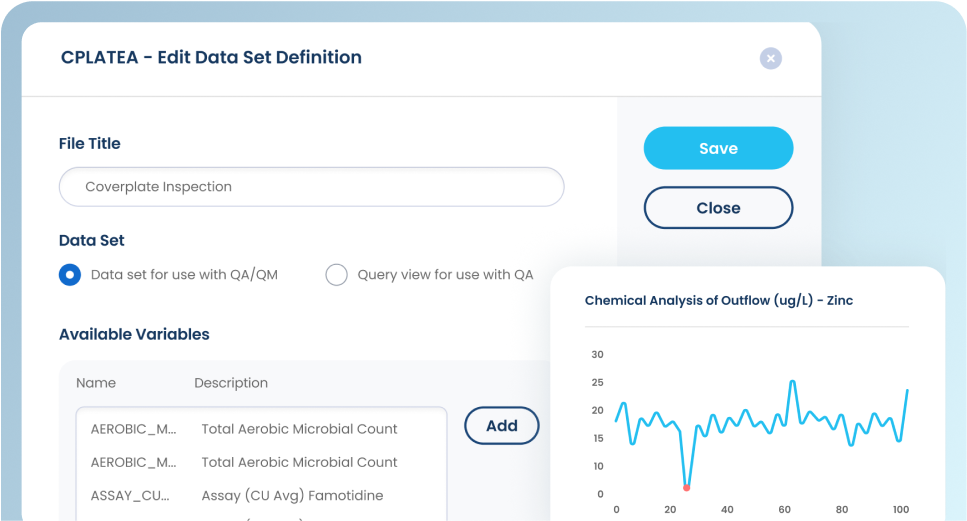

NWA Quality Information System®

Unified data collection solution enables operators to collect data more efficiently and accurately with minimal training.

Northwest Analytics offers customizable manufacturing intelligence and SPC software solutions tailored to the unique challenges and needs of each industry, from petrochemicals to food and materials.

Your success is our priority. We provide expert support, seamless implementation, and responsive service to help you optimize processes and achieve measurable results faster.