Quality Analyst

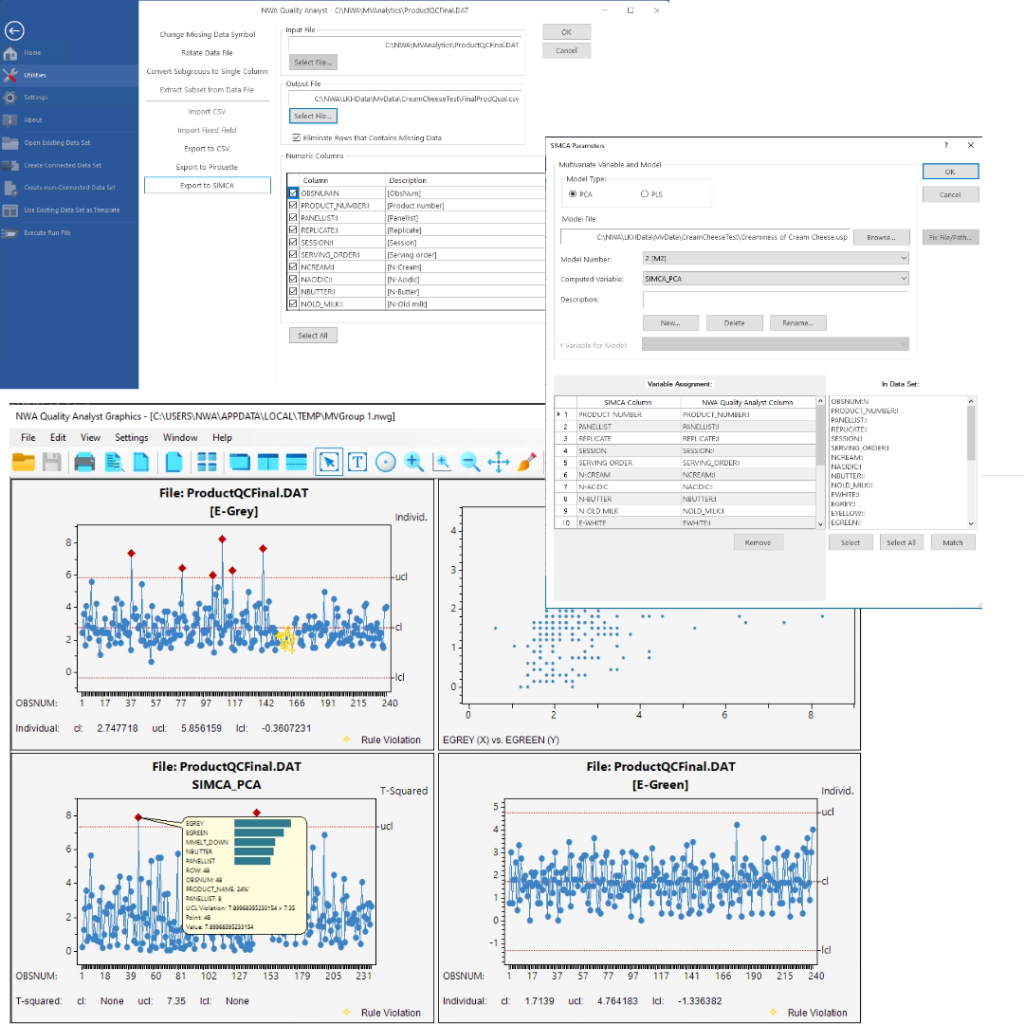

With the future in mind, NWA Quality Analyst® 7 is engineered for peak performance with upgraded technology, updated user interface and database connectivity.

NWA Quality Analyst® is an award-winning SPC charting and analysis software solution that puts the data in the hands of the decision makers with the best combination of power, flexibility, and ease-of-use of any SPC software available. Trusted by manufacturers since 1982, NWA Quality Analyst continues to enable a wide range of users to graphically analyze process behavior to optimize product quality, minimize cost and optimize product quality and reduce risk with minimal training in statistical techniques.

.png)

.png)

.png)

.png)