In today’s global markets, the pressure to perform is non-stop and the need for information is real-time. To maximize competiveness and profitability, the supply chain needs top-notch data management. But, that by itself is not enough. The data must be aggregated and analyzed to deliver complete manufacturing intelligence (MI) that, in turn, enables sound decision making for effective supply chain management.

The Model for Successful Supply Chain Management

Real-time MI enables manufacturers to understand current operational status and to control the process. However, effective supply chain management also requires a model such as Supply Chain Physics to guide those actions.

Supply Chain Physics is a concept based on science, engineering, and business practices. While it is not feasible to articulate and solve the multi-criteria optimization problem that characterizes most supply chain dynamics, Supply Chain Physics provides useful concepts to guide effective supply chain behavior. It is a language and set of principles designed to foster accountability across functions and improvement across the enterprise.

Developed by Mark Gavoor of CR Supply Chain, Supply Chain Physics describes the principles defining supply chain behavior and recognizes the constraints imposed by the movement of goods and services through the supply chain.

Gavoor characterized these principles as the Three Laws of Supply Chain Physics:

- Law of Interdependency – Running a supply chain is a multi-criteria optimization problem. This means constantly trading off Inventory, Quality, Service, and Cost while balancing the needs of customers and the company.

- Law of Constraints - The multi-criteria optimization problem must recognize some very real constraints such as:

- There is a limit to how much can be produced with the existing system.

- There is a limit to how fast and in what quantities goods can be shipped from point A to point B.

- Law of Information - Information drives the supply chain and that information now moves at digital speed. Having the right data, in the right place, at the right time influences decisions regarding lead times, production, inventory, and reactions to market demands.

Prior to modern information systems, information transfer was a major constraint on supply chain management. Now the more common constraint is the ability to aggregate the data, apply suitable analytics and deliver actionable information to support effective decision making.

Sustainable Improvement

Supply chain success is a never-ending process that requires a long term perspective. If the company is going to thrive, the supply chain has to work optimally today, tomorrow and next year. Therefore, supply chain management is not a one-off project but rather involves creating a permanent infrastructure to support operational success.

Supply chain success is a never-ending process that requires a long term perspective. If the company is going to thrive, the supply chain has to work optimally today, tomorrow and next year. Therefore, supply chain management is not a one-off project but rather involves creating a permanent infrastructure to support operational success.

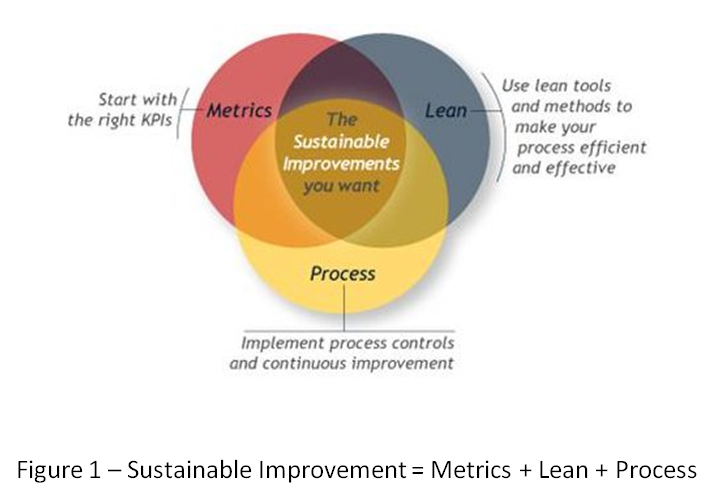

Gavoor summarized the winning strategy as: Sustainable Improvement = Metrics + Lean + Process.

Figure 1 illustrates this relationship and the individual factors are summarized as:

- Metrics – Select the right Key Performance Indicators (KPIs) to properly describe the supply chain process. This is a critical activity since only that which is measured can be managed. A useful overview of current KPI good practices is MESA White Paper #40: Performance Improvement and Metrics Practices

- Lean– Eliminate the non-productive activities and parts of the supply chain process. Use lean tools and methods to make the process efficient and effective and, therefore, a process worth sustaining.

- Process– See all work as process and implement process controls and continuous improvement to maintain system performance and stability.

Each of these factors is critical to supply chain maintenance and thus long-term success. By optimizing each factor and integrating all three, supply chain performance can be sustained indefinitely.

Data and Information Management

Each of the three factors for supply chain management and sustainability depends on good data. Before modern distributed data management systems, information flow in supply chains was slow and often fragmented. As a result, inventory levels in many parts of the supply chain were not visible enough to support good decision making. Too often the process went out of control with disastrous results because the right information was not in the right place at the right time.

Today, with systems such as ERP, data is available everywhere virtually instantaneously. However, to be useful for functions such as supply chain management the data must be accurate and structured to be compatible with other corporate data so that analytics can convert the data into actionable information. This approach provides role-specific reporting to everyone thereby enabling effective decision making to govern supply chain activities.

Note that modern IT services are a double-edged sword since bad data or information is as instantaneously available as good data or information. This requires the ongoing discipline of quality data entry and management. The supply chain manager’s life is good when the information is clean, accurate, up-to-date, and complete.

Intelligence and Improvement

Intelligent simplification enables process improvement. The winning process management and improvement strategy eliminates redundancy and confusion by focusing on a few, well chosen initiatives such as Lean Six Sigma and making process re-engineering a standard part of operations.

Likewise, the MI system provides the integrated analytics and role-specific reporting that focuses attention on only the significant issues. To satisfy the scope of supply chain management the MI system incorporates:

- Direct, non-duplicative access to all data sources (including both process and business data)

- Time-based data aggregation

- Manufacturing analytics

- Role-specific reporting

A capable MI system is the enabling technology for process management and improvement and provides targeted support for critical decision making.

Summary

The goal in supply chain management is to have the right products in the right place at the right time in the right quantities with the right quality – all at the lowest cost. Meeting that goal requires the right data in the right place at the right time with perfect quality.

There is the old maxim attributed to W. Edwards Deming: “In God we trust; all others must bring data." But, while this is true on the tactical analytical level, ERP systems and related technologies have buried the operational decision making process in data of varying usability.

In the larger view, Deming’s quip should be modified to read “… and all others must bring information.” Every part of the global supply chain needs the data converted into actionable information. MI is the means to convert data into information in corporate environments and enable good decision making.

The webinar presented by Mark Gavoor, “The Right Data in the Right Place at the Right Time”, thoroughly examines this systematic approach to supply chain management and improvement.