Top Seven Challenges Implementing A Real-time EMI Solution

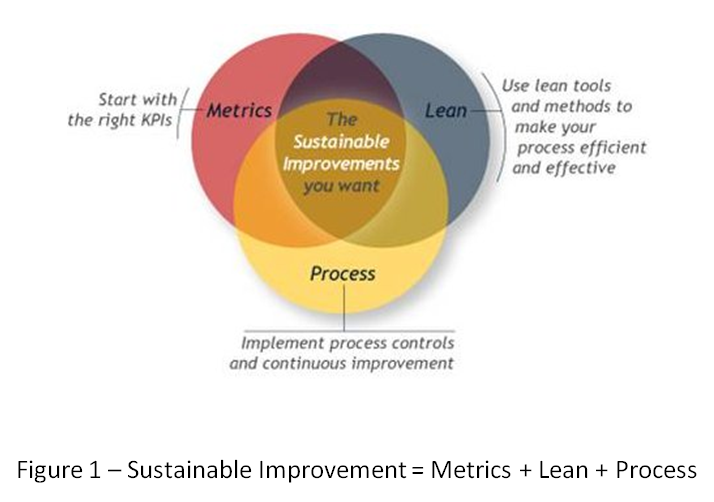

Taking the time to carefully plan the implementation of an EMI real time monitoring system can save weeks of frustration, while creating a tool that quickly achieves results. The goals should be clearly identified in advance, and the planning should carefully incorporate the following steps to ensure goals are met. This document is designed to provide the best practices that other companies have discovered as they developed successful implementations.