The Cost Implications of Improving Fill Weight Control

Modern manufacturing strategy aims to make product to order. If the manufacturer is in a JIT supply chain this is even more critical. Properly done, this approach improves productivity, reduces inventory and cuts lead time.

Modern manufacturing strategy aims to make product to order. If the manufacturer is in a JIT supply chain this is even more critical. Properly done, this approach improves productivity, reduces inventory and cuts lead time.

Today's manufacturer faces an era where the problem is no longer one of not being able to collect enough data on manufacturing processes, but how to effectively use the massive volume of data collected. It is generally accepted that process based manufacturing intelligence is the best path to effective manufacturing enterprise management.

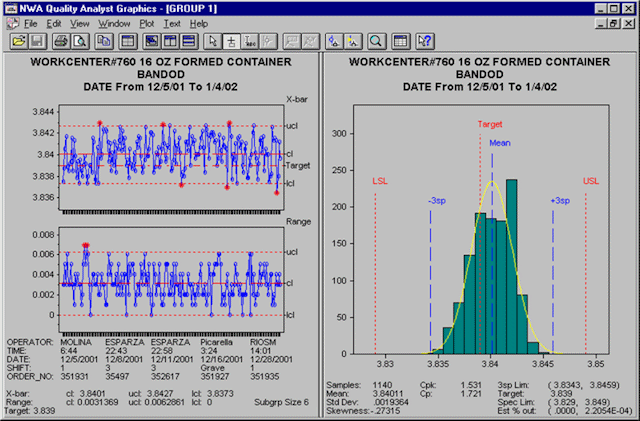

Traditional Quality and Specification Analysis SPC

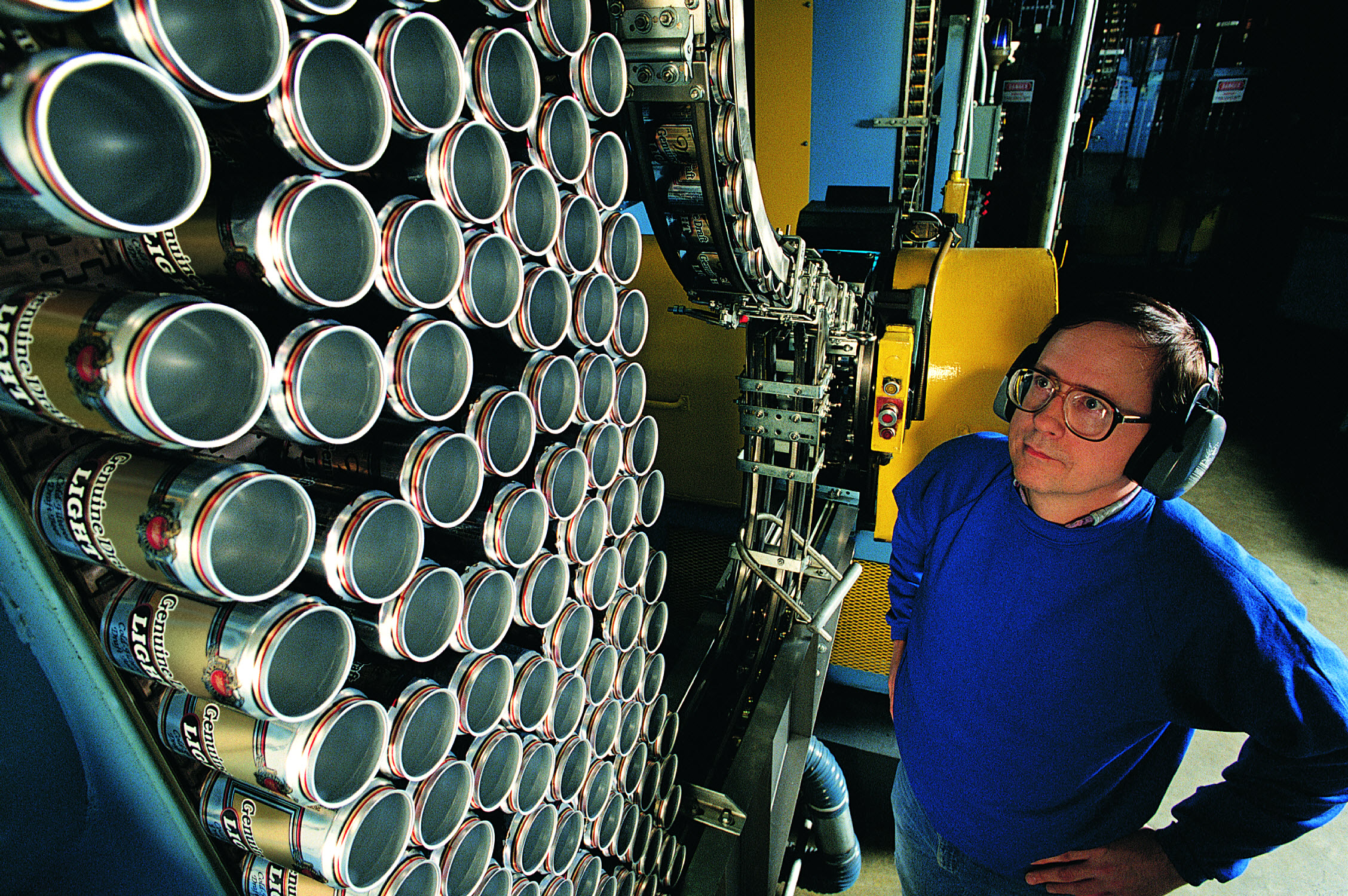

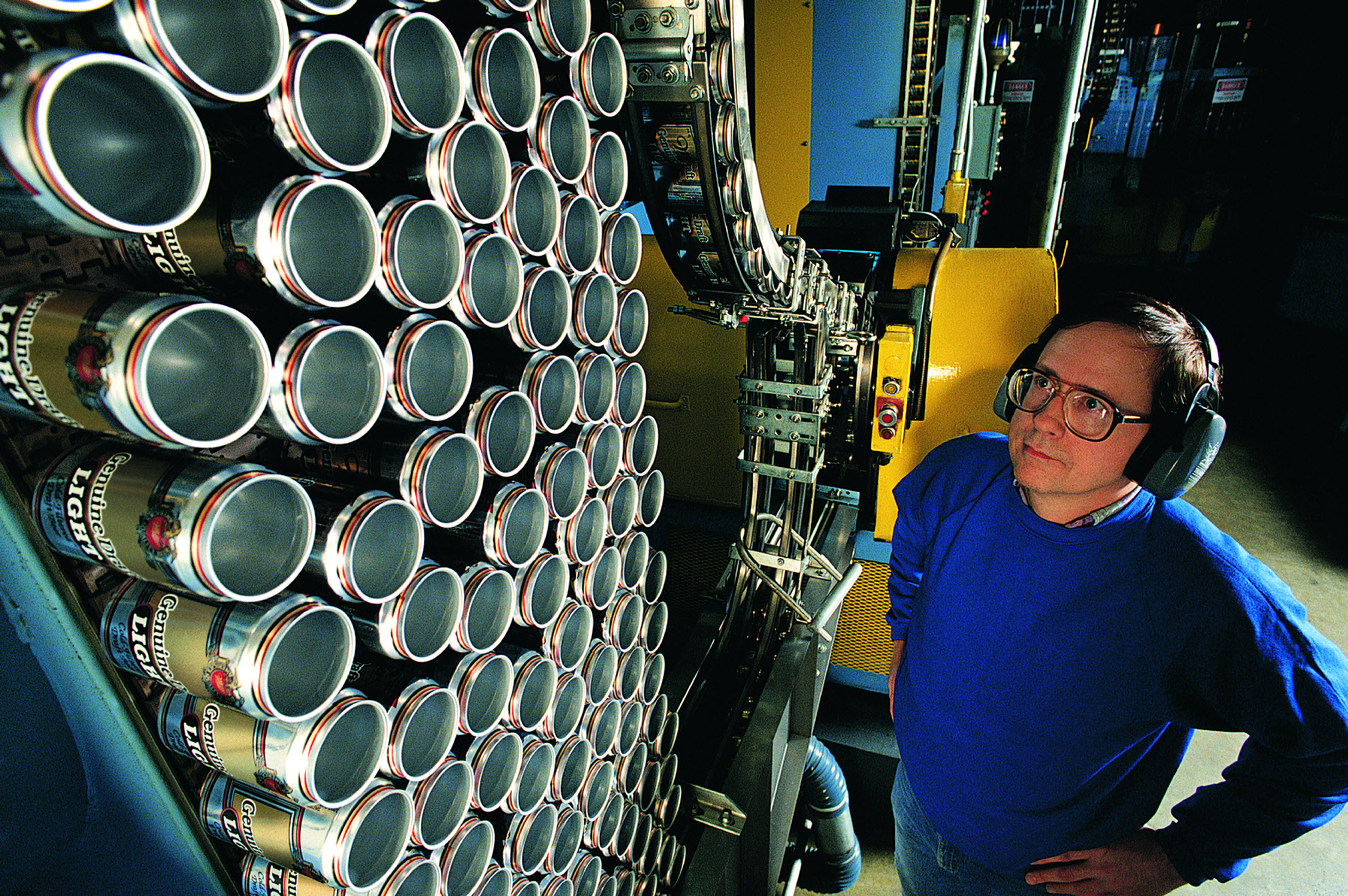

Mounting pressure for product consistency and quality and a mandate to reduce costs spurred container manufacturer Crown Cork and Seal Co. Inc. (Philadelphia, PA) to institute quality measures that could be applied across the board throughout its manufacturing sites around the world. To fully appreciate the size and importance of this task, consider the company's business climate.

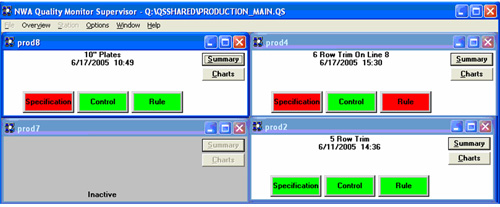

Huhtamaki Americas, headquartered in De Soto, Kansas, operates seventeen manufacturing facilities in North and South America which produce paperboard, plastic, and molded fiber packaging for consumer and food products. The Coleman, MI Huhtamaki facility specializes in plastic thermoforming operations to produce disposable plastic tableware. Using SPC and continuous process improvement methods is the corporate standard process management method and NWA Quality software is the standard SPC software tool.

The Gallo Glass plant in Modesto California is one of world’s largest bottle plants. Fourteen glass lines make more than 100 types of bottles in sizes and shapes ranging from 187 ml single serving bottles to 4 liter jugs. The plant is the sole supplier to the E & J Gallo Winery and produces over 2 million bottles a day.

When glass-container company Saint-Gobain Containers (formerly Ball-Foster Glass Container) implemented a company-wide quality program across its 18 plants, the company standardized its quality data management with NWA Quality Analyst software from Northwest Analytical, Inc.

"Our quality has always been very good, but to be the best in this marketplace, we wanted even higher levels of efficiency, productivity and quality," says Mike Puhl, corporate senior process engineer. "Standardizing on NWA QA has created efficiencies and easy comparisons."