Implementing a sustainable intelligent manufacturing (MI) system

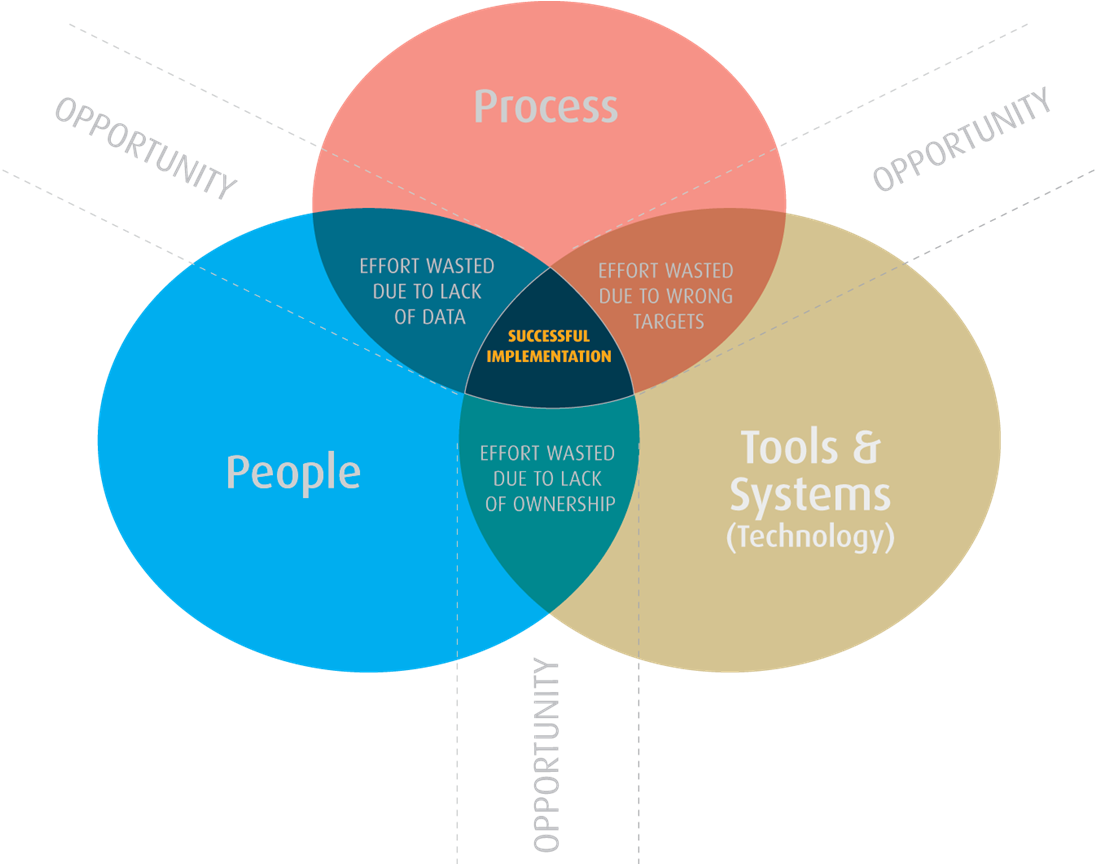

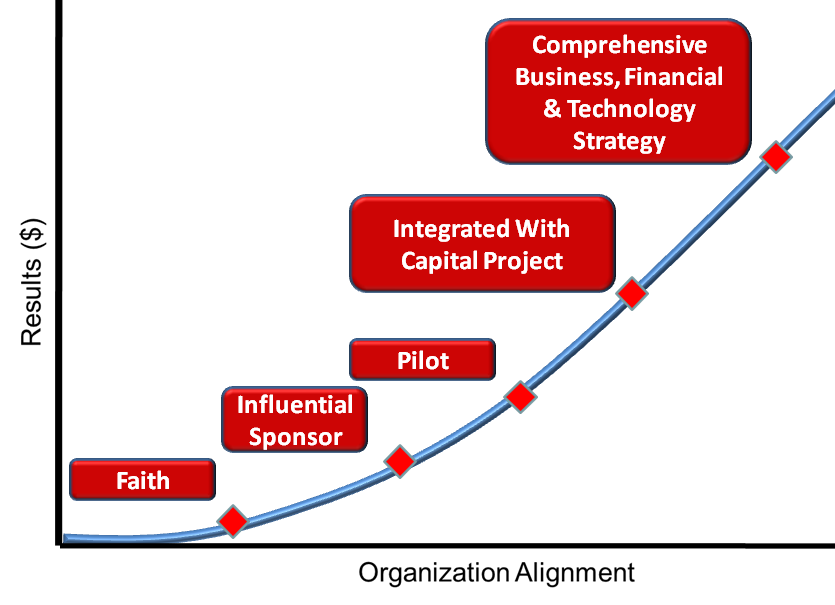

When the company decided to implement Intelligent Manufacturing (MI) system, the usual goal is to achieve a long-term return on investment, the success of the project to provide intelligent decision support manufacturing. The question is how to find a reliable, systematic approach to ensure the success of Intelligent Manufacturing (MI) system it?

Defect problems in complex assemblies are a major headache for both quality staff and management. Not only can the line have unacceptably poor yield due to rejected assemblies, high rework costs threaten profitability of the operation.

Defect problems in complex assemblies are a major headache for both quality staff and management. Not only can the line have unacceptably poor yield due to rejected assemblies, high rework costs threaten profitability of the operation.

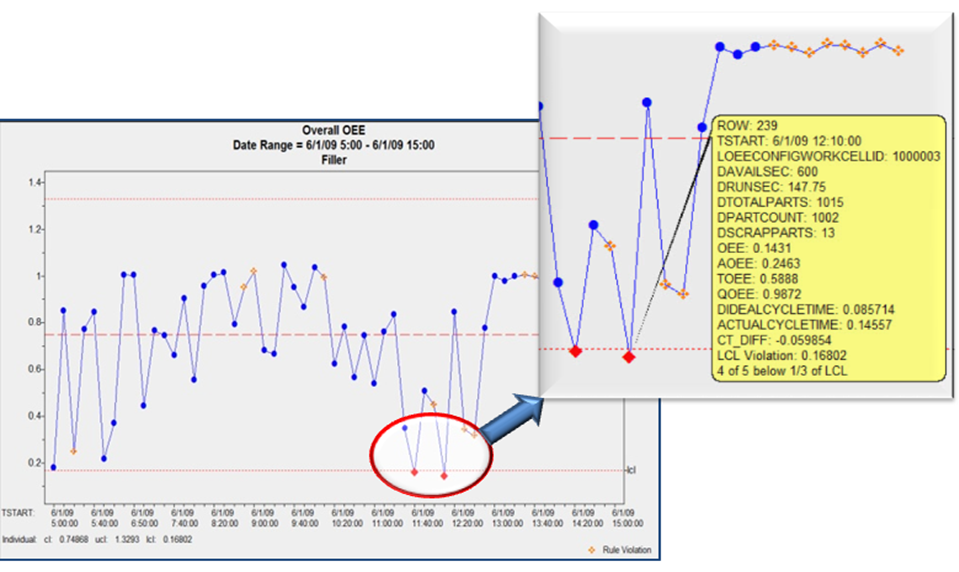

Modern manufacturing strategy aims to make product to order. If the manufacturer is in a JIT supply chain this is even more critical. Properly done, this approach improves productivity, reduces inventory and cuts lead time.

Modern manufacturing strategy aims to make product to order. If the manufacturer is in a JIT supply chain this is even more critical. Properly done, this approach improves productivity, reduces inventory and cuts lead time.