When the company decided to implement Intelligent Manufacturing (MI) system, the usual goal is to achieve a long-term return on investment, the success of the project to provide intelligent decision support manufacturing. The question is how to find a reliable, systematic approach to ensure the success of Intelligent Manufacturing (MI) system it?

Studies have shown that global enterprises have 500-800 billion dollars per year IT projects have failed. The reason ranked first in the study of project failure is failure to achieve the expected business value

System technology project goal is usually not the only cause of failure, and only focus on the management of technology deployment is not enough. Success also depends on the development and management of operational processes using these technologies.

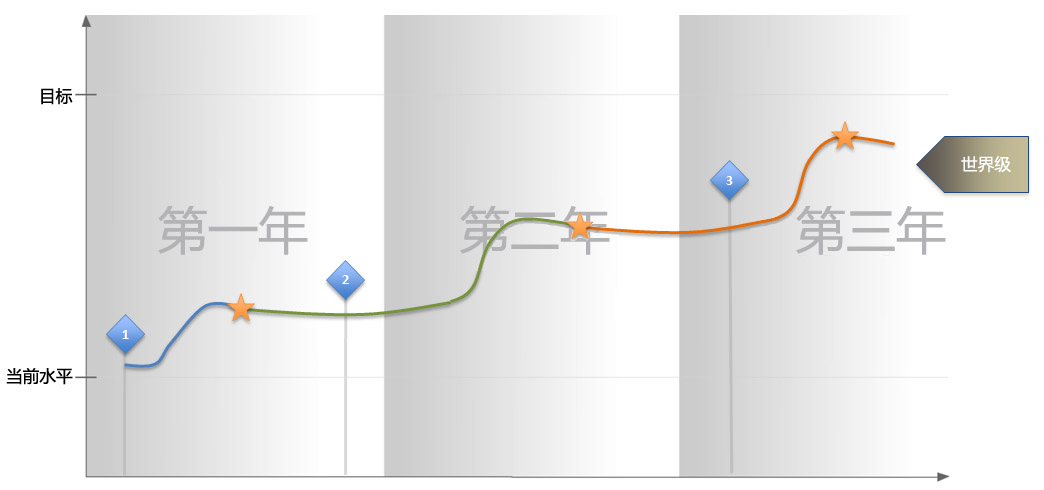

Since the discovery of the Hawthorne effect (Hawthorne Effect) Western Electric Company in the United States since the business has been observed in a number of projects to improve the well initially, but then fell to improve results. If an enterprise lucky enough, to improve the effectiveness of the energy produced by the project's starting point higher than the original level, then the next new project can be carried out from this level until it decays to a lower level (Figure 1). This is similar to the growth cycle of the project brought about ROI is not enough.

Since the discovery of the Hawthorne effect (Hawthorne Effect) Western Electric Company in the United States since the business has been observed in a number of projects to improve the well initially, but then fell to improve results. If an enterprise lucky enough, to improve the effectiveness of the energy produced by the project's starting point higher than the original level, then the next new project can be carried out from this level until it decays to a lower level (Figure 1). This is similar to the growth cycle of the project brought about ROI is not enough.

On the other hand, if the first phase of the project is to improve and maintain the improved embodiment, the second phase of the project is to improve the process can start from a higher starting point (Fig. 2). This is a gateway to the world-class manufacturing capability of the road.

A complete system approach - combining technical skills of internal staff - is the key to the implementation of sustainable management and improvement of manufacturing intelligent manufacturing (MI) systems. The most effective method relies on the establishment of Deming PDCA cycle as the Deming cycle criteria: plan, do, check, act.

Variables found to adjust, and maintain normal effect is also a path to success. This systematic approach to develop a set and technology, people, processes, seamless management program, and so used by MI system can help companies into high-performance, knowledge-driven enterprise. Found that a single element adjustment, enable and sustain effects make this goal feasible.

Discover found

The purpose of discovery is to understand the project planning and development success. The best approach is to follow the ISA95 standards and adjust internal indicators. And quality and process improvement initiatives, like all successful, the most sensible approach is to identify quickly realize the project so that members of the organization involved.

In-depth analysis of operational processes and systems company can develop a successful system to ensure that the desired improvement in the organizational structure in depth all achieve.

In the discovery phase, the project team needs to be checked:

- Enterprise technology needs

- Index adjustment

- Technical capacity

- Management and control systems

- Quantify opportunities for improvement

Align adjustment

This aspect of our goal is to create a task and change the design of the system, the system can be changed and the use of personnel and generate response. "Discovered" this link has allowed the team to establish a management system of a people, process and technology can be connected seamlessly.

Appropriate adjustments to the process to establish a stable and consistent system can:

- Process capability and full compliance with the needs of each stakeholder;

- Improve the effectiveness and potential of each employee for each device;

- By creating a path of least resistance to improve the chances of long-term improvement and success.

When team members assume more responsibility, more support, more efficient cooperation will also deepen the sense of improving management.

Enable Enable

This aspect of our goal is to properly configure the system so that staff understand their respective roles in the management system and to strengthen their sense of responsibility to achieve improvement.

Team can determine actionable data so that the project team and operations management system seamlessly links, in order to ensure that we will be right information at the right time to pass to the right person.

This project can be established:

- Support better information base for decision-making framework;

- Simple, get enterprise-wide knowledge and experience immediately;

- Continued improvement in the ability of companies operating in knowledge-based methods.

Sustain maintain

Our goal is to be able to continue to assess and strengthen the deployment process management system to ensure that the value of MI can be achieved over time. Implementation process systems, training series, audit and advocated the establishment of a sustainable and transferable process to continually optimize your process manufacturing operations.

These steps create a sustainable and transferable programs basis for continuous optimization of your process manufacturing operations, enabling employees to actively participate in the company to a high-performance, knowledge-driven organizational transformation.

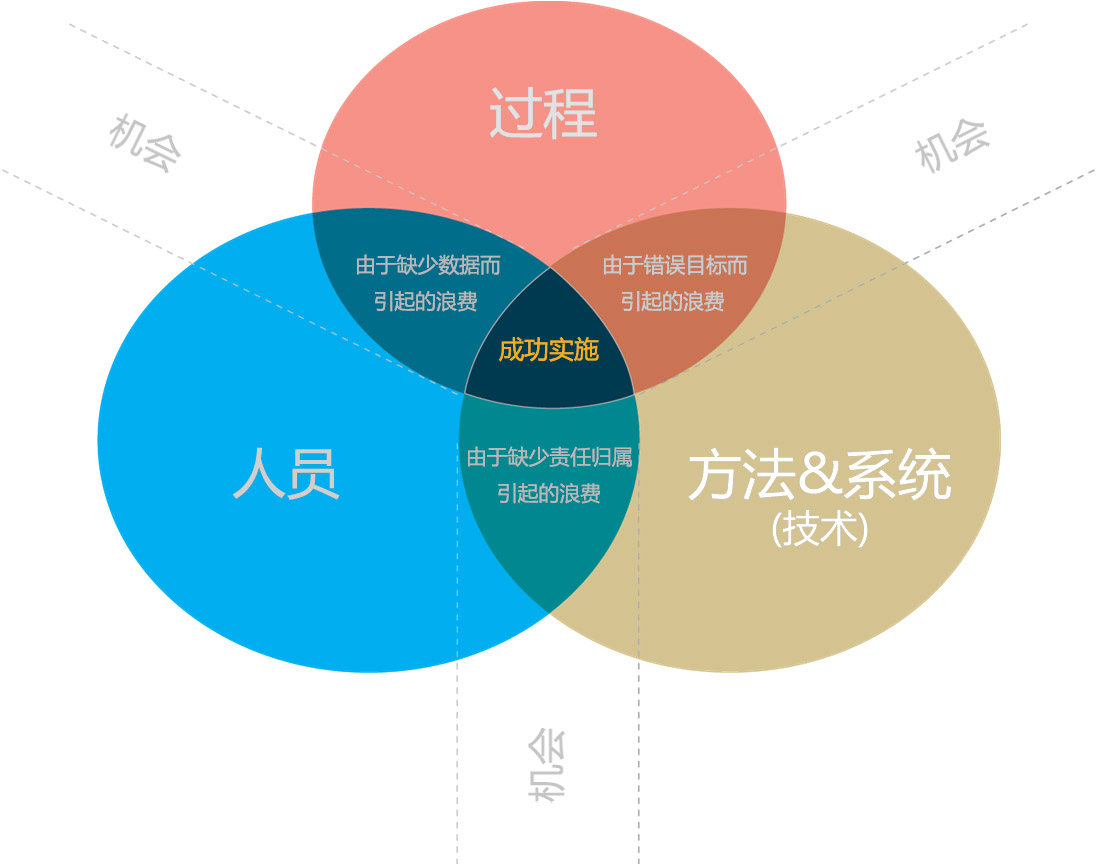

For the people, process, technology focus and balance to achieve the best state to make the project operational, to ensure the successful implementation (Figure 3). Every successful elements have the following characteristics:

- Process-centric

- Been shown to produce value in the right customer

- The use of technology continues to drive value

- Provide ongoing management sessions platform

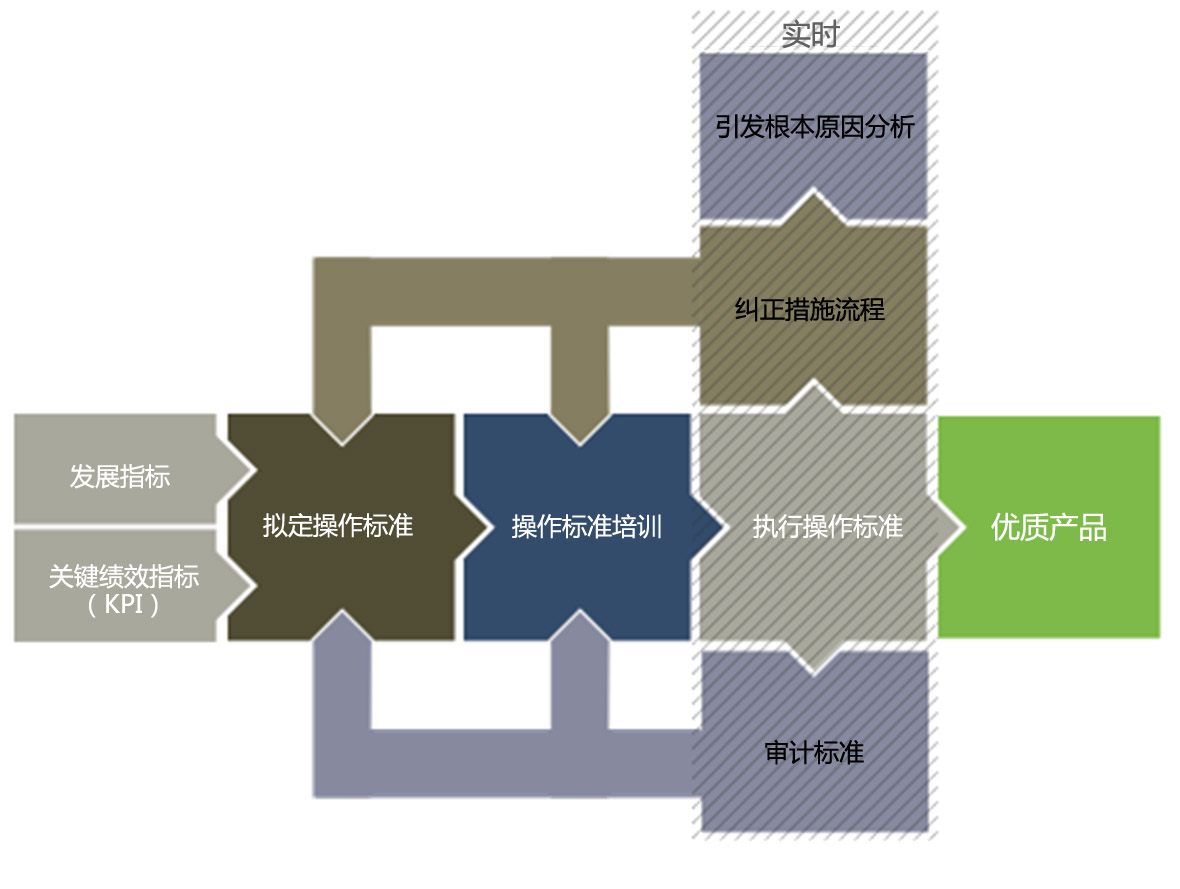

Quality product is the end result expected. To achieve this ultimate goal, the system will need to define the characteristics of content characterization process, such as: the production process, SOP, metrics and KPI. Ideally, employees at all levels are involved in the definition process. Employees need to accept a variety of training, including procedures and quality standard plan, corrective actions, and so on. The whole process is regarded as operating system specific technical basis, the technical system is critical, but not practical, unless the process to continue to develop, the ability to continue to give full play to the staff (Figure 4).

Summary Summary

Common industry problems are easy to implement project management systems and part of the concern is more difficult for people to postpone part of the system that is used in everyday life and work. However, if you want to develop a successful and sustainable production management system, companies and employees need to be given the same degree of attention.

The system must be done is easy to use, and achieve and corporate culture, even though time goes by, employees from running, but the system is still able to operate successfully. This is not only the internal requirements for this system, while the system also needs to meet external standards such as ISO 9001: 2008, ISO 22000, both of which require the system to continue to meet the audit from all sides.

Intelligent Manufacturing (MI) is an important part of the enterprise infrastructure, which provides reports based on different roles, so that everyone in the target company agreed to complete their tasks successfully. Production Intelligence (MI) strategy for success lies in the ease of use, technical and interpersonal skills are easy to implement active integration.

After the desired outcome rational design and implementation of the system are:

- Break the cycle of limited results, increase ROI, maintain results;

- Effective use of available resources from senior management to the baseline operator;

- Layers to build a successful example for the company personnel;

- To establish the effect of maintaining these objectives management system in the following ways:

- Responsibility

- Setting the standard

- Through the file to explain the process

By combining more than a few words about the technology, people, processes to develop long-term outcome after efficient production intelligence (MI) system can be realized. This discussion is based on the Rob Bansek SightBridge Consulting speech at a seminar, the theme of his speech was: " EMI systematic implementation - to survive just another milestone. " You can click to listen to the seminar for free.