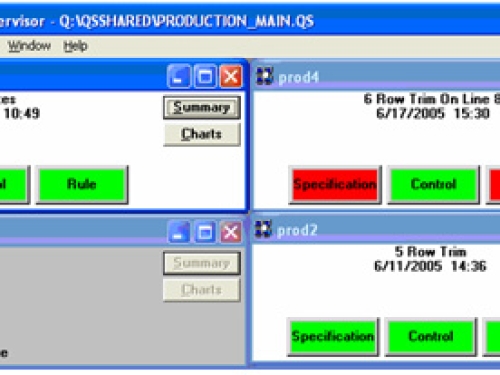

Software: NWA Quality Monitor

A manufacturer of advanced composite products adopted NWA Quality Monitor from Northwest Analytical to help meet demanding aerospace industry quality standards. Now the software is delivering benefits to many other aspects of the Company’s business.

“What we really liked about Quality Monitor was the way we could use templates to replicate our paper travellers on screen. That way our production people could build on a familiar environment rather than having to learn an entirely new approach.”