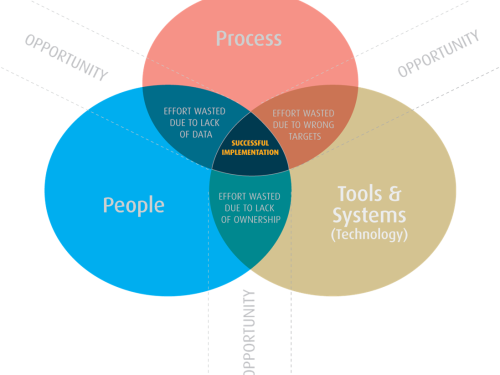

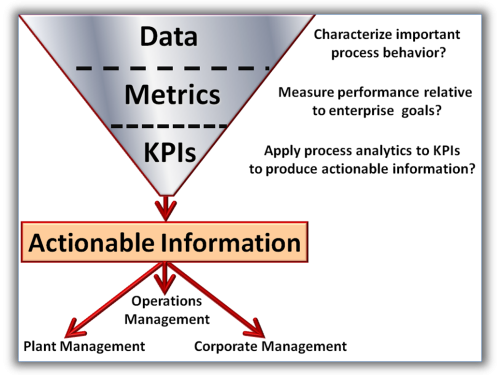

When the company decided to implement Intelligent Manufacturing (MI) system, the usual goal is to achieve a long-term return on investment, the success of the project to provide intelligent decision support manufacturing. The question is how to find a reliable, systematic approach to ensure the success of Intelligent Manufacturing (MI) system it?