Hazard Analysis Critical Control Point is a food safety management system designed to ensure the safe production and packaging of food. The HACCP process (Table 1) has both strengths and limitations. It provides a systematic and effective method to analyze a process, and identifies potential biological, chemical and physical hazards that can occur in food. In addition, HACCP requires the development of strategies to prevent the inclusion or reduction of these hazards to an acceptable level in the food.

- 888-692-7638

- 111 SW Columbia Street, Suite 1080, Portland OR, 97201, USA

- White Paper/ 07 Jun, 2011

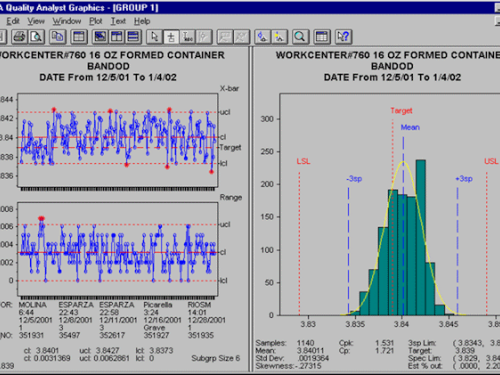

Today's manufacturer faces an era where the problem is no longer one of not being able to collect enough data on manufacturing processes, but how to effectively use the massive volume of data collected. It is generally accepted that process based manufacturing intelligence is the best path to effective manufacturing enterprise management.

Traditional Quality and Specification Analysis SPC

- Case Study/ 07 Jun, 2011

Kettle Foods maintained the quality of the artisan potato chip and scaled up from a small-scale craft operation to high-volume production.

- Case Study/ 07 Jun, 2011

Overview

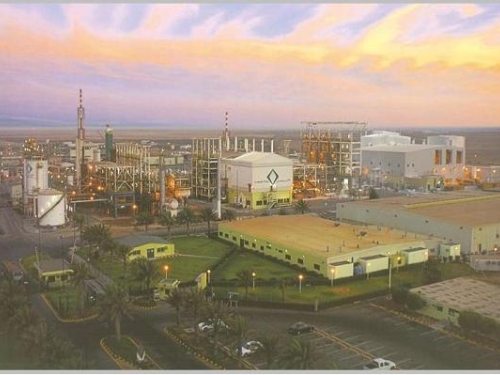

The National Titanium Dioxide Company Ltd (Cristal) has been manufacturing titanium dioxide (TiO2) using imported rutile ore at its ultra-modern Yanbu Al-Sinaiyah plant in Saudi Arabia since 1991. National markets its products under the well-known Cristal brand.

- Article/ 07 Jun, 2011

Revised: April 1998

formerly "Statistical Quality Control and Printed Circuit Board Manufacturing"