The Challenge

90% of the world’s data has been created in the last two years, yet many companies find they are not looking at the right data, in the right way, at the right time. Yet that’s exactly what’s needed as pressures increase to reduce costs, increase yields and improve quality in an environment of higher competition and customer demands.

90% of the world’s data has been created in the last two years, yet many companies find they are not looking at the right data, in the right way, at the right time. Yet that’s exactly what’s needed as pressures increase to reduce costs, increase yields and improve quality in an environment of higher competition and customer demands.

For manufacturers, the issue isn’t lack of data. They generate plenty of data with their existing systems. The challenge is converting that data into the intelligence needed to make real-time actionable decisions

Unfortunately current manufacturing systems, while capable of handling their original missions, are ill-equipped to deliver the manufacturing intelligence essential to be efficient and profitable today.

Current manufacturing information and process control systems are good at collecting lots of data and managing specific processes, but they fail at delivering the real-time analytics and cross-system integration and aggregation required to produce the manufacturing intelligence required to address the market’s top needs.

As a result, managers, engineers, and operators lack the real-time visibility and intelligence they need to recognize problems quickly and make fast, informed decisions.

![]() For a manufacturer to achieve true, enterprise-level manufacturing intelligence, their solution at a minimum must deliver in real-time:

For a manufacturer to achieve true, enterprise-level manufacturing intelligence, their solution at a minimum must deliver in real-time:

- Cross-platform data integration;

- Data contextualization and aggregation;

- Comprehensive, robust analytics

- Powerful, role-based visualization;

- Propagation to all stakeholders and enterprise-level systems.

The Solution – NWA Focus EMI®

Leading operations require the real-time analysis of data from any and all processes in order to react with quick, educated decisions. This makes EMI one of the top requirements for high-performance manufacturing. The ARC Advisory Group recently detailed the Top 10 Best Practices for EMI Success. NWA Focus EMI® exceeds all of them.

Next Generation EMI

NWA Focus EMI goes far beyond basic EMI to focus the right people, on the right issues, with the right information and solutions at the right time.

Northwest Analytics picks up where simple EMI systems leave off, efficiently combining data, analytics and real-time visibility for a new level of manufacturing intelligence for intelligent manufacturing. The secret? NWA Focus EMI spans all manufacturing process systems and data sources with an easily deployed integration layer without adding redundant storage or interfering with existing infrastructure operations.

Focus EMI compliments, amplifies and multiplies the value of existing systems to integrate, aggregate and analyze process data in real-time to deliver role-specific visualization of the true operating status. NWA applies leading manufacturing analytics to deliver complete manufacturing intelligence capability for immediate and significant payoff.

NWA Focus EMI Core - Real-time process data integration, analytics and visualization

The NWA Focus EMI Core platform delivers real-time process analytics and visualization services from existing manufacturing data sources.

- Direct connectionsto all major process databases (Historians, LIMS, MES, etc.) via industry-standard integration technology with support for ODBC, OLEdb, OPC, and user defined SQL and without requiring redundant data storage.

- Simplified data modelingusing highly granular Data Set definitions that simplify and speed implementation across multiple data sources, creating the data, context, and analytics definitions needed by a comprehensive EMI solution.

- Role-specific, configurable dashboardsmonitoring Key Quality Indicators from multiple sources in real-time, with alerts based on specifications, SPC limits, trends, or unusual patterns; and instant access to exception reports, drill-down capability, and SPC charts to deliver the information needed to make the right decisions at the right time.

- Comprehensive analytics for off-line problem solving, process capability analysis, continuous process improvement, investigation, and routine process management and reporting.

- Notification Servicesdelivering active alarm and status informationfor automatic, immediate e-mail and SMS (text message) notification that include issue-specific information and graphics.

- Web-based publishingfor instant distribution of the most current analytics and reporting across the enterprise.

|

Industry EMI Definition* |

NWA Focus EMI Core Functionality |

|

Data Integration & Aggregation |

Aggregates data from all process sources such as Process Historians, LIMS and Quality Information Systems, MES, ERP as well as custom (be-spoke) and dedicated sources. |

|

Data Contextualization & Modeling |

Provides structure for defining data aggregated across multiple data sources and supports established models such as ISA-95. |

|

Analysis |

Includes a full suite of manufacturing-centered analytics including SPC, pattern and trend detection, process capability, and support for advanced methods such as multivariate modeling. |

|

Visualization & Reporting |

Delivers real-time, role-based visualization dashboards to support decision making throughout the enterprise. |

|

Propagation |

Pushes reporting on all available network and web based infrastructures. |

Accelerated EMI

NWA Focus EMI utilizes unique technologies to define next-generation EMI today…”Accelerated EMI”.

Accelerated EMI uses fast and simple direct data connections to tap into existing data silos (Process Historians, LIMS, plant floor systems or spreadsheets). No data duplication requirements. No data warehouses.

NWA further accelerates EMI through two, key differentiating modules - NWA Focus KnowledgeBase™ and NWA Collaboration™ - to capture and proliferate best practices. These unique functional modules accelerate the ability to resolve pressing operational issues through manufacturing-focused collaboration.

KnowledgeBaseTM – Focusing Accumulated Knowledge and Experience

NWA Focus EMI KnowledgeBaseTM extends the reach of core EMI functionality by allowing manufacturers to accumulate and disseminate knowledge across the entire enterprise based on existing expertise and best practices.

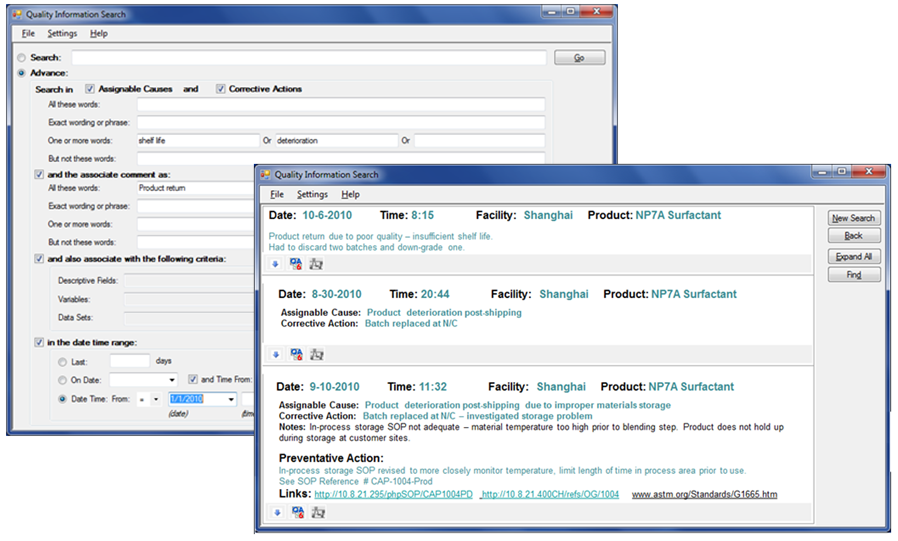

KnowledgeBase provides searchable centralized management of accumulated process improvement information, assignable cause/corrective action inputs and issue-resolution knowledge. Operations experience and best practices are automatically accumulated and organized, creating a repository of accessible, proven manufacturing process solutions. KnowledgeBase delivers this information, associated notes and analytics across the enterprise. Additional relevant information can also include external references and links to expand access to intranet and internet resources.

KnowledgeBase provides searchable centralized management of accumulated process improvement information, assignable cause/corrective action inputs and issue-resolution knowledge. Operations experience and best practices are automatically accumulated and organized, creating a repository of accessible, proven manufacturing process solutions. KnowledgeBase delivers this information, associated notes and analytics across the enterprise. Additional relevant information can also include external references and links to expand access to intranet and internet resources.

Information in KnowledgeBase is quickly and easily searchedvia the user-friendly Search Engine, optimized to quickly identify when similar problems have been solved previously or at other facilities. This produces the right course of action more quickly, re-enforcing best practices and ensuring that problems only have to be solved once.

NWA Focus EMI KnowledgeBase At A Glance

- Collects and consolidates process, quality and problem-solving knowledge

- Links process events to a rich information base including external resources

- Search results include full-context AC/CA, analytics, and associated data

- Supports shared knowledge and best practices across multiple shifts, locations

KnowledgeBase is a cornerstone solution supporting a well-informed workforce that contributes to and utilizes the knowledge accumulated through problem solving and best practices.

Focus EMI Collaboration – Focusing the Right Players on the Right Solutions

Real-time role-specific visibility is often the primary support for individual decision making, however, many operational issues require getting the right people together to analyze a problem and quickly produce the optimum solution. With more remote employees and geographically-dispersed operations than ever, collaboration and sharing information becomes increasingly important.

NWA Focus EMI Collaboration provides fast, robust and simple communications for both real-time and asynchronous collaboration, using rich content documents that integrate text, graphics, pictures and video. Content can be quickly and easily delivered as a simple link in an email. This eliminates the issues of sending large file sizes through the corporate email system and avoids concerns about firewalls.

Focus EMI CollaborationTM helps develop a well-informed workforce that can jointly take the next step for effective EMI implementation. The collaboration builds trust and enables greater interaction across the organization, bringing everyone into an informed conversation, removing barriers and driving continuous improvement.

NWA Focus EMI Collaboration enables both real-time and asynchronous group sharing of observations and decisions with the immediacy of email and the clarity of a web live meeting to provide more rapid and effective resolution of process management and improvement issues.

NWA Focus EMI Collaboration enables both real-time and asynchronous group sharing of observations and decisions with the immediacy of email and the clarity of a web live meeting to provide more rapid and effective resolution of process management and improvement issues.

Focus EMI Collaboration also provides the side benefit of being an active content contribution source for KnowledgeBase. This continuously builds corporate knowledge to speed competence building, quickly graduating one-time procedures to established processes.

NWA Focus EMI Collaboration Center At-a-Glance

- Significantly faster problem resolution by immediate sharing of important information with subject-matter experts

- Capitalizes on expertise and experience across the enterprise

- Richer information content accessible in a concise package with narrative

- Reduces meeting time and diminishes geographic and time zone constraints

- Supports continuous improvement initiatives for less waste and increased profits

- Continuously grows corporate value by contributing Best Practices to the KnowledgeBase

Accelerating Time-to-ROI

NWAFocus EMI is the shortest path to the ultimate full-functioning, scalable and accelerated EMI solution.

NWA Focus EMI’s accelerated approach to delivering value isn’t limited to the use of the solution itself. NWA Focus EMI accelerates the implementation process as well to for quickest time-to-value, full solution payback, and overall ROI.

Time-to-value is measured in hours, not weeks. NWA Focus EMI’s unique data integration approach allows for unparalleled data-source connectivity speed. Analyzed data can start being visualized for users in the first 4-8 hours of implementation.

A full implementation of NWA Focus EMI takes a mere 1-3 weeks. Combined with the solution’s high usability and accelerating modules, the average solution payback is only 2-6 months from implementation completion. After deployment, as issues are found and solved through greater collaboration, the knowledge base grows and customer satisfaction is increased for an accelerated and measurable ROI..

NWA Accelerated Implementations

NWA takes the lead every step of the way to develop and implement the perfect EMI solution specifically crafted for each organization.It starts with understanding corporate objectives. Existing methods and infrastructure are evaluated and a plan is formulated. Implementation is accomplished in a surprisingly short period of time with the assistance of both NWA and appropriate NWA business partners. Once installed NWA is there to train users and trainers. It’s all part of getting the best EMI solution in place with the least amount of time, money and resources to realize ROI as quickly as possible. From beginning to end, it truly is accelerated EMI.

- Assessment – Inventory existing legacy manufacturing systems, data structures and the data contained therein

- Review existing system resources and structure

- Develop roadmap for full EMI capability

- Match available data and analytics to user's needs (role-specific content)

- Implementation – Optimal time to a functional, complete system is critical for maximum effectiveness

- Install, connect and test EMI functions

- Train staff for ongoing maintenance

- Training – Train staff onusing NWA Focus EMI for decision support for maximum results

- Train-the-trainer – Extend training reach and create long-term self-reliance for internal training

- From onsite or at NWA corporate headquarters, Northwest Analytics provides a variety of training option to bring end-users up to speed quickly.

- Advanced Services – NWA Focus EMI brings change to operational management models that require careful planning for maximum ROI.

- Guidance in deriving value

- Pre- and post-install ROI (scoping, realization)

- Application of analytics to manufacturing processes

Focus the right resources, on the right issues, with the right answers.

Learn more about how NWA Focus EMI bridges data silos and applies industry-leading analytics to enable fast, informed, collaborative decisions. Focus on manufacturing intelligence for intelligent manufacturing™.